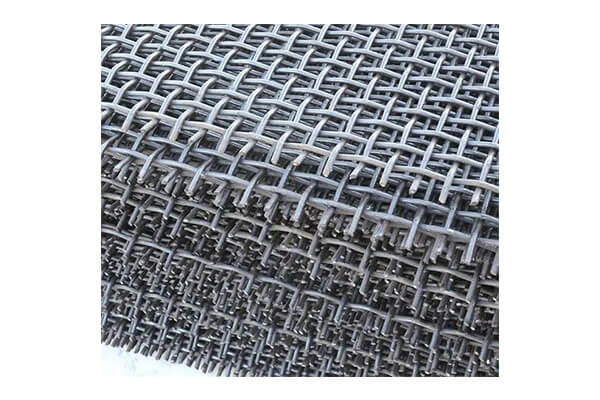

Vibrating screen mesh are important components in material sieving, and they are susceptible to damage due to their fine wire diameter, high pressure resistance, and long wear and tear. To ensure effective sieving, it's necessary to promptly replace the screen mesh. The materials that come into contact with the screen can vary greatly, and there are various types of screen mesh available. Screen mesh are commonly categorized based on their material into metal screen mesh and non-metal screen mesh. Metal screen mesh materials include stainless steel, copper (brass, bronze, phosphor bronze), high carbon steel, low carbon steel, manganese steel, and spring steel, among others. Non-metal screen mesh materials include nylon, rubber, and polyurethane, among others.

Stainless steel screen mesh are a versatile screening material suitable for the vast majority of materials. They offer multiple advantages, including corrosion resistance, high-temperature resistance, wear resistance, rust resistance, and an attractive appearance. They have a wide range of applications and can be found in various fields such as mining, petroleum, chemical, food, pharmaceuticals, mechanical manufacturing, construction decoration, electronics, aerospace, and more.

Copper screen mesh, on the other hand, differ from stainless steel screen mesh. They are chosen for materials with special requirements (such as heavy metal content) and for dry samples. Copper screens exhibit good mechanical properties, good machinability, and a certain degree of oxidation and corrosion resistance. They are widely used in industries like abrasives, geology, metallurgy, pharmacopeia, chemical, and construction materials for precise particle screening and particle size analysis.

Manganese steel screen mesh, also known as abrasive screens, have high strength and exceptional wear resistance, making them capable of withstanding harsh conditions such as impact, compression, and material abrasion. As a result, manganese steel screen mesh are extensively used in the screening of materials like silicon carbide, brown corundum, white corundum, diamond, cubic boron nitride, diamond powder, aluminum powder, and other abrasive and powdered materials.

Polyurethane rod screen mesh and polyurethane dewatering screen mesh are two different names for the same type of polyurethane screen mesh with a steel wire rope core. Polyurethane screen mesh are manufactured using high-quality imported first-grade polyurethane materials, and their wear resistance is five times that of traditional manganese steel screens.

Polyurethane screen mesh have the following characteristics:

1, Excellent wear resistance and long service life: Their wear resistance is 3-5 times that of steel screens and over 5 times that of regular rubber screens.

2, Minimal maintenance requirements: Polyurethane screen mesh are not easily damaged, have a long service life, which significantly reduces maintenance and downtime losses.

3, Good resistance to moisture: They can operate in conditions with water as the medium, are corrosion-resistant, non-combustible, and non-toxic.

4, High screening efficiency: Due to the characteristics of secondary vibration, polyurethane screen mesh have a self-cleaning effect. Moreover, in the presence of water or oil, the friction coefficient between polyurethane and the material is reduced, enhancing screening efficiency.

5,High screening precision: Thanks to well-designed screen openings and a unique manufacturing process, particles of the utmost dimensions will not block the screen openings, greatly improving screening precision.

6,Energy-efficient and reduced consumption: Polyurethane has a lower density, making it significantly lighter than steel screen mesh of the same size. This reduces the machine load, saves electricity, and extends the screen's lifespan.

7, Low noise operation: They operate with low noise levels, complying with national environmental noise standards. Polyurethane screen mesh have excellent shock-absorbing properties.

Tailored Screen Mesh:

-

Customizing the length and width dimensions of the screen mesh to precisely match the size of the screening machine.

-

Customizing the mesh size of the screen mesh according to the specific requirements of the material being screened.

- Selecting the mesh opening ratio of the screen mesh based on the properties of the screened material, the required screening efficiency, and the operational intensity.