OVERVIEW

A packaging machine, also known as a variable frequency micro-powder quantitative automatic packaging machine, automatically fills micro-powder and micro nano-powder into various forms of sealed packaging bags, such as sleeve bags and valve bags, while simultaneously measuring the quantity of the material being filled. It offers high filling efficiency and accurate measurement, which can significantly improve production efficiency, save labor, and reduce the labor intensity of workers. Additionally, since packaging is done in a sealed state, it reduces environmental pollution and enhances the working environment for employees.

During the packaging process, the vacuum dust collector is used to recover any scattered powder, reducing waste and consumption of the finished product. Furthermore, the presence of air holes in the packaging process reduces the air content and the high-speed material ejection rate, which increases the compression of the powdered material, leading to increased bulk density. In comparison to packaging machines without compression functionality, this results in higher packaging quantities and cost savings.

ADVANTAGES

The core rotating components are cast with a thickness of over 10mm, making them durable and resistant to deformation, with excellent stability.

Multi-level variable frequency design ensures high packaging accuracy. The weighing accuracy exceeds the national standard of ±0.2%. The machine unit combines a single screw infinitely variable speed feeding system for precise weighing while simplifying the structure by eliminating complex hydraulic lifting devices. This approach achieves higher accuracy and speed, offers simplicity in design, ease of operation, and reduces maintenance requirements.

It uses a top-tier international brand inverter to adjust the feeding speed. This allows for continuous and stable frequency control, ensuring reliable performance.

The PLC (Programmable Logic Controller) system provides centralized control, and it can be configured with a touchscreen human-machine interface (HMI) for convenient adjustment and parameter settings. This system facilitates online networking and remote control. The electrical control cabinet is designed with a separate dustproof structure. It can be equipped with an explosion-proof control system to meet the packaging requirements for conductive materials.

Dust-free operation, low noise, no spillage, and reduced powder consumption. The machine is designed with an environmental protection concept, incorporating advanced dust removal technology and devices. Dust and sealing mechanisms are employed at both the material intake and bag clamping points to prevent dust dispersion, ensuring a clean working environment.

It employs an imported electronic weighing system for automatic measurement, automatic material discharge, and automatic shutdown. The weighing system utilizes electronic scales, with the weighing sensors having a protection rating of IP65. The weighing control display instrument is imported and digital, equipped with features such as automatic tare adjustment, automatic zero calibration, automatic error correction, exceeding tolerance alarms, and self-diagnostic functions.

Finished products are conveyed using roller conveyors, making it easy for hoisting and transportation.

The machine can be configured with a packaging buffer bin as needed, depending on the requirements and the material storage situation at the site. Also it can be equipped with a sealed compartment to prevent powder leakage, promoting environmental protection and material savings.

WORKING PRINCIPLE

This machine has a framework structure and is fully enclosed to ensure the cleanliness and reliability of electrical and pneumatic components. It consists of several key components:

Feeding Mechanism The feeding mechanism comprises a small material hopper, a controllable discharge valve, and a level sensor. The hopper stores a certain amount of material needed for packaging, and the material level is controlled by the level sensor to maintain consistency during the packaging process.

The small material hopper stores the required material for packaging. The quantity of material in the hopper is determined by the desired packaging volume, and it is important not to overfill to ensure precision.

The level sensor, typically a rotary type, monitors the material level in the hopper. It sends signals to the PLC to control the discharge valve's operation. When the material level is low, the valve opens to refill the hopper, and when the level reaches a certain point, the valve closes to stop material flow.

The controllable discharge valve can be a rotary star-type valve or a pneumatic butterfly valve, and it is chosen by the user.

Conveying Mechanism The conveying mechanism consists of a motor, an impeller pump, and nozzles. The motor powers the machine and drives the impeller pump, which propels the material in a tangential direction. Additional pneumatic pressure assists in ensuring a smooth material flow into the packaging bags.

The motor's speed is controlled by a frequency inverter, allowing for variable speed adjustments based on the specific material being handled.

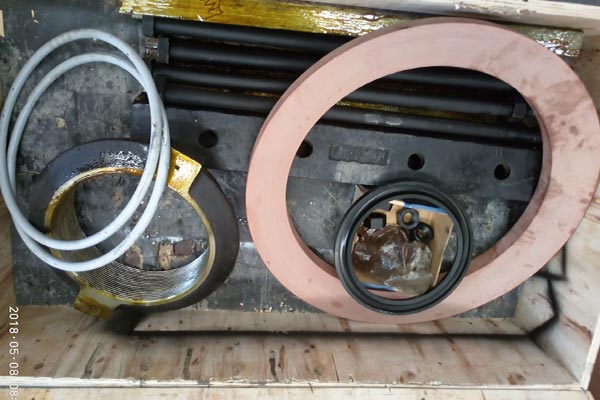

Material Transfer Control Mechanism The material transfer control mechanism includes two symmetrically acting cylinders, electromagnetic valves MV3 and MV4, pressure regulators, flexible connecting hoses for material transfer, and bidirectional stops for cylinder movement. This mechanism controls the material flow into the bags.

Pneumatic Auxiliary Material Transfer Mechanism This mechanism includes material transfer pressure and powder clearing air. Material transfer pressure assists in pushing the material smoothly, and its magnitude depends on the material's density, humidity, and flowability. Powder clearing air is used to blow the remaining measured material into the packaging bag at the end of a bag-filling cycle.

Weighing and Measuring Mechanism The weighing and measuring mechanism comprises a weighing suspension device, tension load cells, weighing brackets, soft rubber pads connecting the system to the machine, and a weighing suspension device. This system accurately measures the weight of the material to be packaged.

Dust Collection and Recovery Mechanism This mechanism includes an interface for connecting to a dust collector and a dust collection pipe. The negative pressure from the dust collector helps recover any material that scatters during the packaging process, reducing material waste.

The combination of these components allows the machine to efficiently and accurately package a variety of powdered materials, making it a versatile and reliable packaging solution.