OVERVIEW

Impact crusher is a kind of crushing equipment using impact energy to crush materials with medium hardness. Impact crusher is characterized by high crushing ratio, well-distributed final product size with little over-gringding materials, cubic shape products without crack, wide adjusting range, selective crushing, etc. It is of reasonable structure, wide usage, high efficiency, simple operation and maintenance and excellent safe performance.

ADVANTAGES

-

High chrome hammer is new type wear-resistant material, which is allowed longer working life. The whole rotor owns good dynamic and static balance and impact resistance.

-

Integral cast steel structure is adopted for bearing seat, and radial strength of the bearing seat is highly strengthened.

-

The unique splint and wedge are matched in the plate hammer fixing device, which makes the plate hammer much more reliable, and easier to change.

-

Hydraulic adjustment device is used, so the discharging size can be changed quickly, reducing the downtime and maintenance time.

-

Equipped with hydraulic frame opening device, and the spare parts such as hammer can be changed quickly.

- Clear working division and accurate positioning, three-chamber type is suitable for tertiary crushing, and two-chamber type is for primary and secondary crushing. The production size tends to be cubic shape. Discharging size can be adjusted, and simplifying the crushing process.

WORKING PRINCIPLE

Impact crusher crushes material by striking energy. When it works, the motor drives the rotor assembly rotate at a high speed, on which the blow bar is installed. As soon as the material get into the affecting area of the blow bar, they will be stroke by the blow bar and be thrown to the impact devices around the rotor assembly. The high speed forces the material to rebound from the impact liner to the area where the blow bar effects until they have been crushed to the required size. The clearance between the impact racks and the rotor can be adjusted to change the size and shape of the end products.

Impact crusher adopts springs behind the impact racks as the safety devices. The impact racks would be drew back by the springs, as soon as unbreakable materials get into the crushing cavity, till the materials be discharged from the outlet.

Attention: Iron or other unbreakable materials shouldn’t be fed into the crusher, or the impact crusher would be terribly damaged.

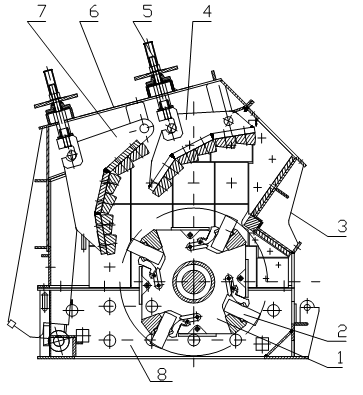

1.rotor 2. hammer 3. central case 4. front impact rack 5. suspension system 6. back upper rack 7. back impact rack 8. Seat

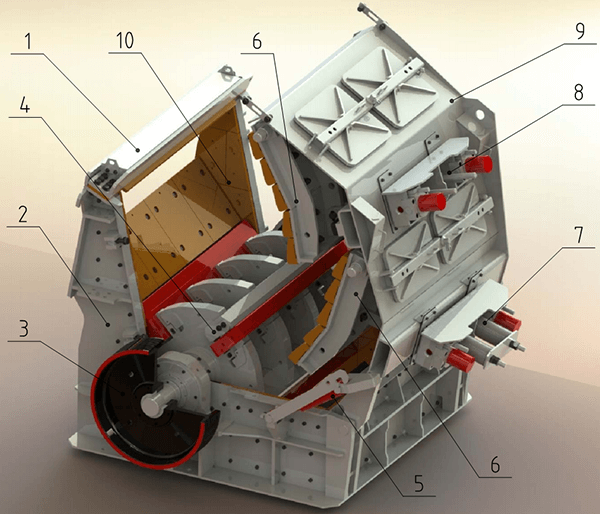

PF Impact crusher

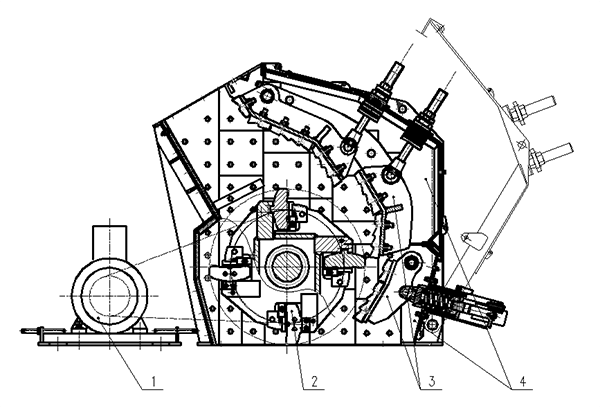

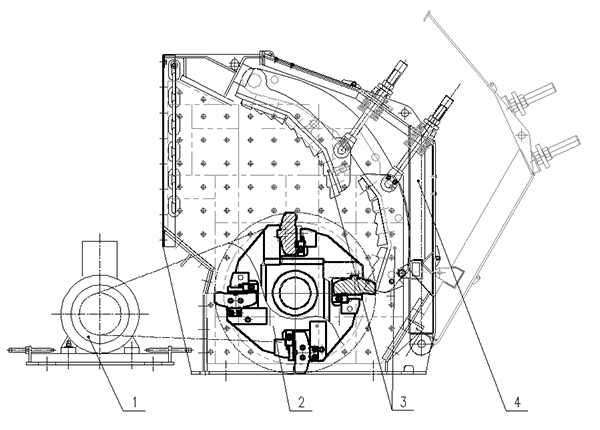

PFW series Impact Crusher is composed of the rotor, impact racks, main frame, screw-rod lifting devices (or hydraulic lifting devices) and driving shaft assembly, etc.

PFW with three crushing chambers

PFW with two crushing chambers