OVERVIEW

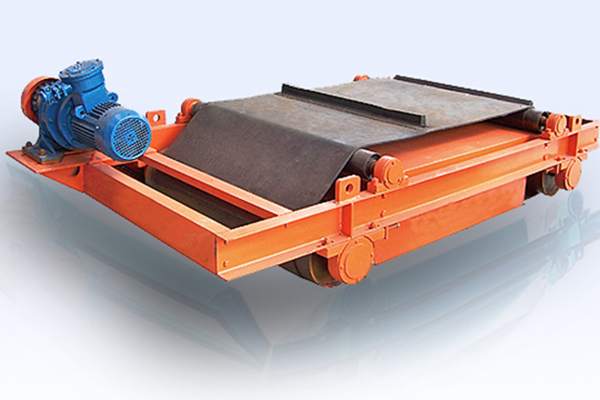

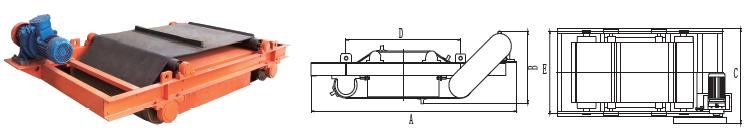

The RCYD series magnetic iron seperator(also called permanent magnetic self-unloading iron remover) is equivalent to the RCYC series and is suitable for iron removal from raw materials on conveyor belts in various industries. It can continuously and automatically remove iron. The belt features an automatic correction function, ensuring reliable operation and easy maintenance. Its internal magnetic circuit adopts a sophisticated magnetic pole structure, ensuring the entire system's effectiveness and performance.

The design and manufacturing of the iron remover comply with the JB/T8711-2006 standard. The magnetic field exceeds the national standard by 3mT and can be tested on-site with detection equipment. High-strength rare earth materials, such as neodymium, iron and boron are used for the internal magnetic components, offering a high purity of neodymium, iron, boron and a large quantity, resulting in a strong magnetic force. This enables the effortless removal of ferromagnetic impurities weighing from 0.1 to 35 Kg from the materials in operation.

The suspended permanent magnetic iron remover is often used in conjunction with belt conveyors, vibrating conveyors, electromagnetic vibrating feeders, and discharge chutes to remove ferromagnetic materials weighing between 0.1 and 35 kilograms that may be mixed within bulk materials.

ADVANTAGES

Easy installationIts compact size and ease of installation make it a versatile choice.

User-friendliness and long lifespanThis equipment is equipped with a fully automated timing control system for customer selection. It can control the iron removal conveyor belt to automatically run and remove iron at specified intervals. It also automatically stops after a certain period of iron removal operation. This not only effectively reduces energy consumption but also extends the lifespan of the belt and motor. It eliminates the need for complex equipment control procedures that would otherwise be connected to a central control system.

Reliable operationIt does not need control circuits, ensuring reliable and fault-free operation. Its extended lifespan and low maintenance requirements make it well-suited for continuous operation, especially in situations where there is a limited presence of ferromagnetic substances. It does not experience temperature rise issues. The magnetic field remains constant, and when power is disconnected, any ferromagnetic impurities attracted to the iron remover do not fall back into the material. There are no concerns about insulation or pressure resistance, making it an excellent choice for businesses that require long-term operation.

Minimal maintenanceThe drive drum features a conical shape, providing automatic correction capabilities. This effectively prevents the occurrence of belt misalignment when the iron removal conveyor belt is running at high speeds. The fully sealed cast steel bearing seat serves to prevent a significant amount of dust from entering the bearings, which could be harmful, and enhances the lifespan of the bearings while ensuring the smooth operation of the equipment.

Strong magnetic propertiesIt is made from special types of permanent magnets, such as neodymium iron boron.

Saving energyThe permanent magnetic iron remover does not require electrical power/energy to function, offering significant energy-saving benefits.

High efficiencyIt can effectively remove ferromagnetic impurities weighing from 0.1 to 35 kilograms in a single operation.

WORKING PRINCIPLE

The RCYD series magnetic iron seperator(permanent magnetic self-unloading iron remover) consists of several components, including neodymium iron boron permanent magnetic cores, the iron removal conveyor belt, a reduction motor, a frame, and a drum. It is designed for use in conjunction with various conveyor systems and is primarily used to automatically remove ferromagnetic materials from non-magnetic materials, especially in scenarios where the material contains a significant amount of iron.

As granular materials pass directly beneath the permanent magnetic self-unloading iron remover, ferromagnetic impurities mixed within the material, weighing approximately 0.1 to 35 kilograms, are attracted to it. Since the belt on the iron remover is continuously in motion, when the iron material adhering to it passes through a non-magnetic zone, it is scraped off by the iron pieces on the belt and deposited into a collection box. This process achieves the continuous and automatic removal of iron from the material.