When the plate hammers are worn to a certain extent, they should be adjusted or replaced promptly to prevent damage to fasteners and other components. The adjustment methods for different plate hammer types are described below:

When the plate hammers are worn to a certain extent, they should be adjusted or replaced promptly to prevent damage to fasteners and other components. The adjustment methods for different plate hammer types are described below:

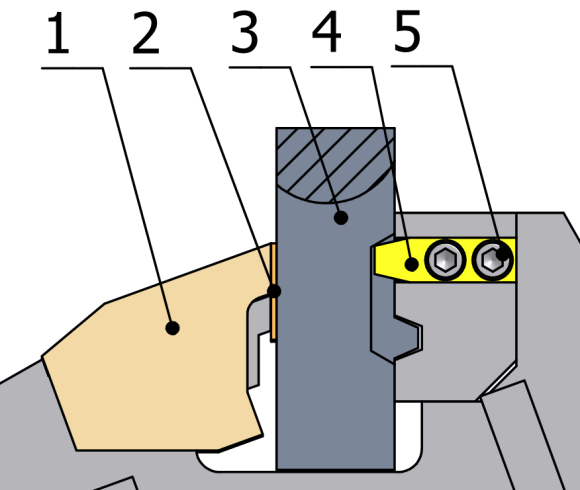

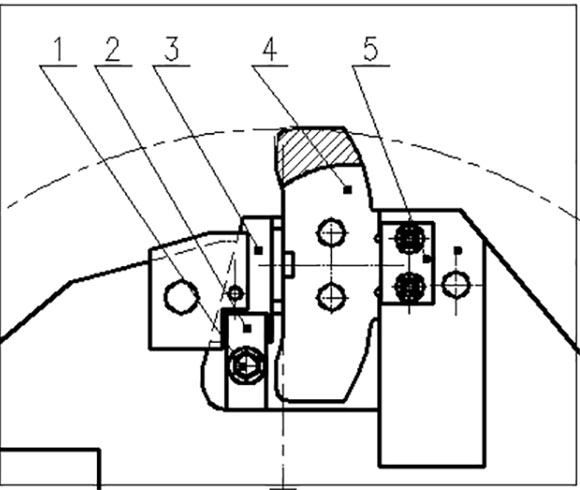

For PF1010 Hammer Adjustment:

1.Wedge 2.Gasket 3.Hammer 4.Baffle 5.Screw

Before adjustment

After adjustment

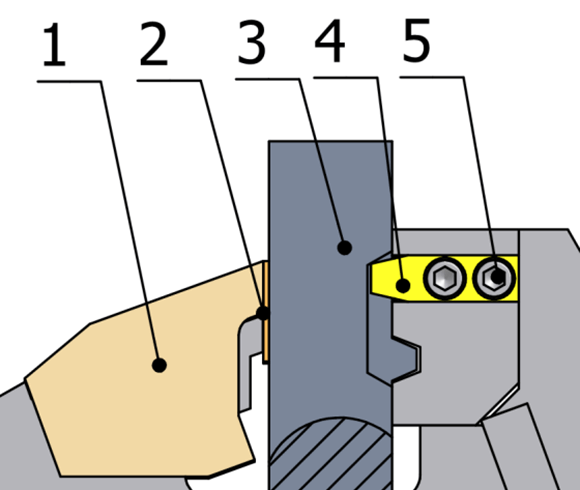

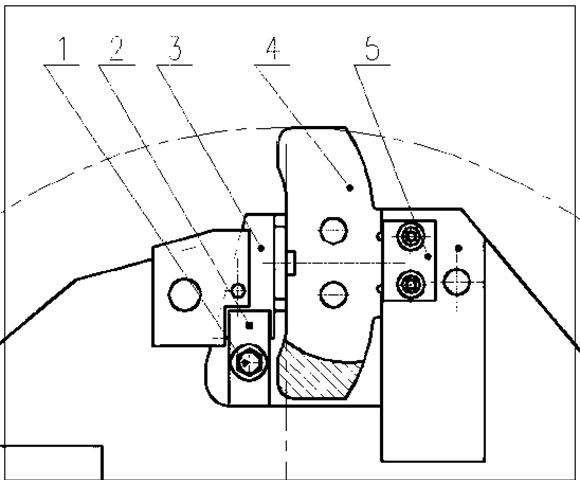

For PF1210 and PF1214 Hammer Adjustment:

1.Protective Plate 2.Baffle 3.Pressing Block 4.Hammer

Before adjustment

After adjustment

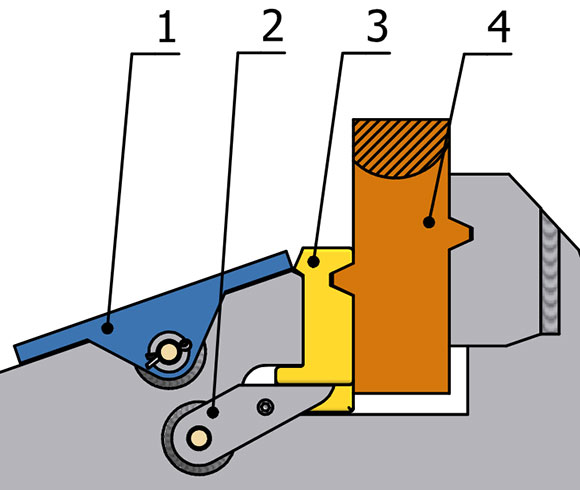

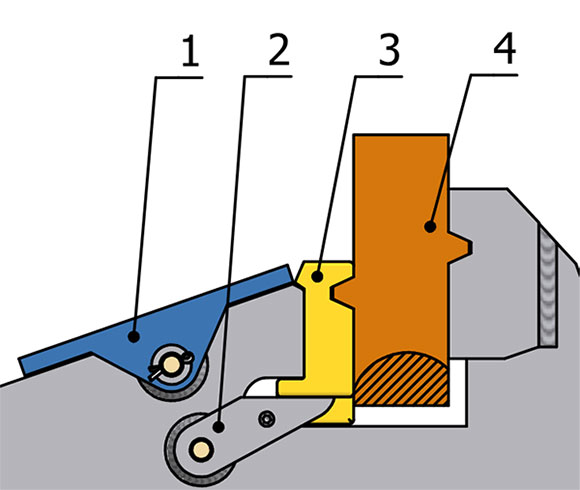

For PF1315 Hammer Adjustment:

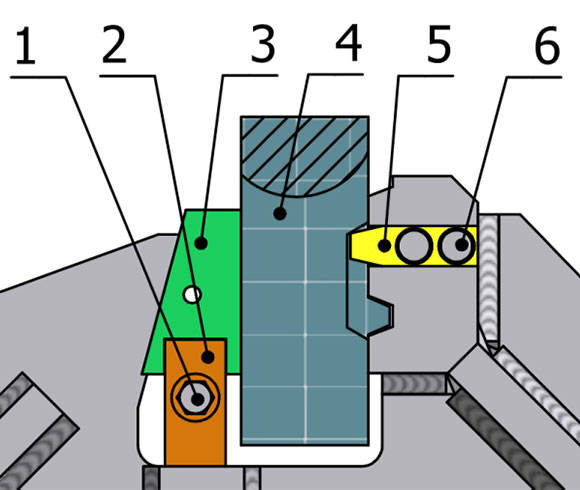

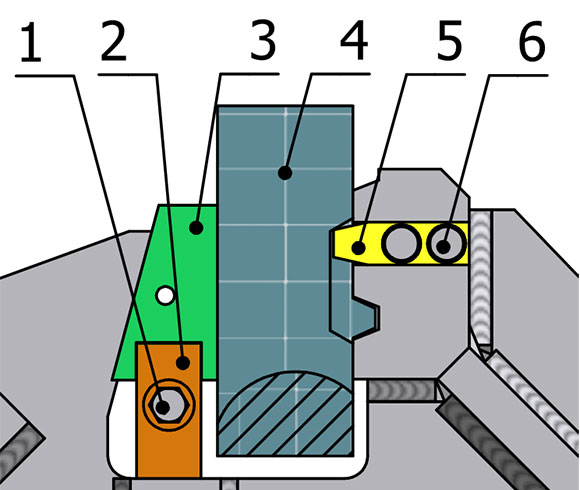

1.Bolt Assembly 2.Clamp Plate 3.Wedge Block 4.Hammer 5.Baffle 6.Screw

Before adjustment

After adjustment

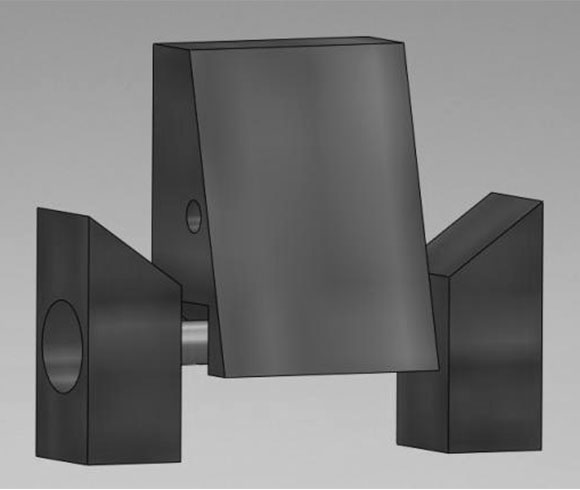

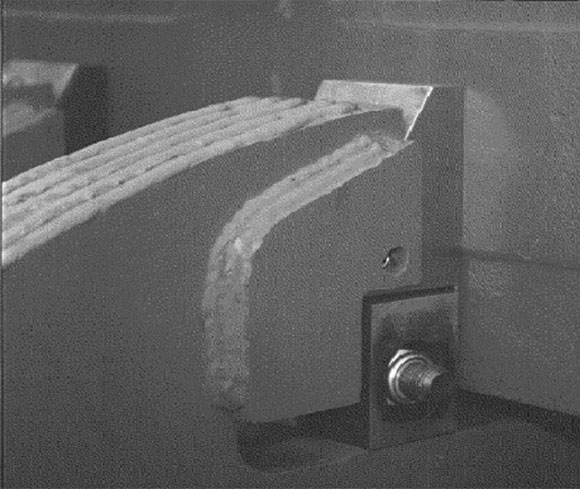

For PFW series Hammer Adjustment

Plate hammer clamping components

Plate hammer clamping state

Before adjustment

After adjustment

For PF1010 Hammer Replacement:

1.Remove the baffle 2. Remove the gasket 3. Pull out the hammer

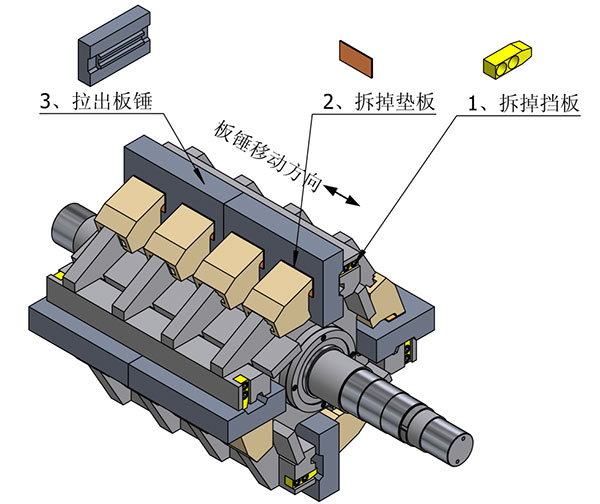

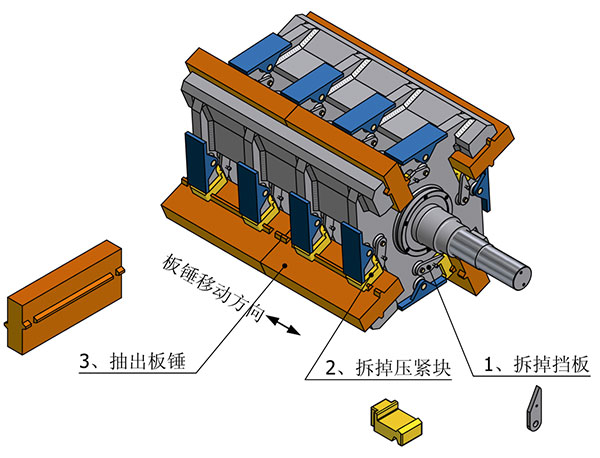

For PF1210 and PF1214 Hammer Replacement:

1.Remove the baffle 2. Remove the pressing block 3. Pull out the hammer

For PF1315 Hammer Replacement:

1.Remove the baffle 2.Remove the clamp plate 3. Remove the wedge block 4.Pull out the hammer

To adjust or replace the plate hammers, follow these steps:

-

Use a ratchet flip device to open the rear upper frame.

-

Rotate the rotor manually to position the plate hammers that need adjustment or replacement to the maintenance door.

-

Secure the rotor in place.

-

Remove the plate hammer positioning components: First, adjust the positioning components to the appropriate position, then disassemble the fixed plate hammer baffle, pressure block (or clamp plate, wedge block) along the axis.

-

Then push the plate hammer along the axis out through the maintenance door or hoist it out from the middle of the frame. When disassembling, gently tap the plate hammer with a mallet.

-

When installing plate hammers, reverse the above steps.

-

Note: Install plate hammers of approximately equal weight in corresponding positions to avoid imbalance during operation. Severe vibration can significantly impact bearing life and disrupt the normal operation of the equipment.