OVERVIEW

Blowers(centrifugal fans) are commonly used as the primary source of power for dust collectors, playing a crucial role in dust collection systems. If the fan for a dust collector is not correctly matched, it can result in suboptimal dust collection performance. Therefore, it's essential to select the right fan for a dust collector to avoid inefficient dust collection.

The typical fan type used in pulse-jet dust collectors is the centrifugal fan. Centrifugal fans are known for their extended start-up times and higher initial current (approximately 6-8 times the rated current). This results in significant mechanical stress on the motor and the fan of the dust collector, which can shorten their operational lifespan.

By using variable frequency drive (VFD) fans, you can achieve soft starting and stopping, which minimizes the mechanical stress on the dust collector's motor. This significantly extends the operational lifespan of the equipment. Adding a VFD to the dust collector fan allows for smooth and stable airflow adjustments. Operators can easily control the fan's parameters, leading to improved efficiency.

Fans with VFD capabilities can maintain stable operation within a high-precision range of 0.1 to 0.01 Hz. With VFDs, dust collector fans can often operate at speeds 150 RPM lower than the original fixed speed, reducing wear and tear on the fan's impeller. This reduction in wear and vibration effectively extends the maintenance interval of the dust collector fan, saving on maintenance costs and downtime.

ADVANTAGES

Greater Airflow and Pressure: Centrifugal fans utilize the centrifugal force principle, allowing them to generate larger airflow and pressure, making them effective for ventilation and exhaust applications.

Simple Structure: Compared to other ventilation equipment, centrifugal fans have a straightforward and easy-to-maintain design.

Various Models: Centrifugal fans come in various models to meet different needs, including single inlet centrifugal fans, double inlet centrifugal fans, forward-curved blade centrifugal fans, backward-curved blade centrifugal fans, radial blade centrifugal fans, centrifugal exhaust fans, and more.

WORKING PRINCIPLE

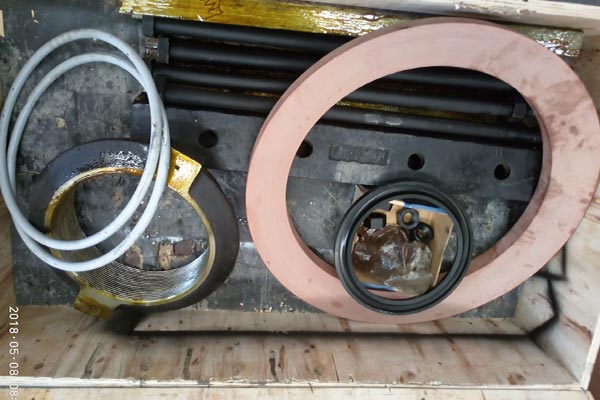

A blower(centrifugal fan) primarily consists of components such as a motor, volute casing, impeller, inlet and outlet ports, duct connections, centrifugal fan oil plug, and an inlet plenum. The motor is powered by an electrical source and drives the rotation of the impeller. The impeller is the central component of the centrifugal fan, and factors like its speed, outer diameter, and blade angles affect the airflow rate and air pressure generated by the fan. Additionally, the material of the impeller significantly influences the fan's durability and reliability.

The volute casing serves the purpose of converting the kinetic energy of the rotating impeller into static pressure, thereby increasing air pressure. The inlet and outlet ports are used to introduce and exhaust air, while the duct connections facilitate air transportation. The centrifugal fan oil plug is utilized for lubricating the fan's bearings to reduce wear and improve its longevity. The inlet plenum is used to enhance inlet kinetic energy and eliminate variations in air velocity.

The working principle of a centrifugal fan involves the motor driving the high-speed rotation of the impeller, which results in the generation of kinetic energy and pressure in the incoming air. As a consequence, the outgoing air experiences air pressure and airflow. During the fan's rotation, the fluid is subjected to centrifugal forces, causing a change in its state. Since the pressure at the inlet is lower than at the outlet, the fluid is drawn into the fan from the inlet, flows in the axial direction along the impeller's centerline, is propelled outward by the centrifugal force, and, in the process, experiences an increase in air pressure. Finally, the air is discharged through the outlet, achieving purposes like ventilation, smoke extraction, and air exchange.