OVERVIEW

Single cylinder hydraulic cone crusher with independent research and development is a newly and high-efficiency crusher, based on our over 20-year experience on design, production, sales and service, combining with the development of modern industrial technology, and widely embracing advanced crusher technology in the United States, Germany and other developed countries. Single cylinder hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc., representing the most advanced crusher technology in the world. It is not only widely applied in medium, fine and super fine stone crushing industry, but also in such industries as metal and nonmetallic ore, cement, construction, sand making, metallurgy, etc. Besides, it is suitable to crush iron ore, non-ferrous metal ore, granite, limestone, quartzite, sandstone, pebble, etc.

ADVANTAGES

-

Inter-particle crushing works between materials that increase the working life of mantle and bowl liner.

-

Provide a more consistent gradation and superior cubic products. Better performance in the construction and sand making field.

-

Real-time displays the specification of crushing, hydraulic and lubrication in operation

-

It can realize unmanned operation by continuously measuring and automatic setting system.

-

Dynamic adjustment of motor power and crusher pressure under working reduces the unnecessary losses made by human error and maximize energy into production.

-

The CSS can be adjusted on load.

-

The flexible gradation adjustment will save the production cost while increasing the benefits.

-

Constant load setting: The CSS will be adjusted automatically according to the changes of the feeding size, moisture and hardness of the material and make sure the load of the crusher is constant.

-

Constant CSS setting: Once the CSS is set, the output will be kept by continuously measuring and compensating for crusher liner wear.

-

The mantle has basic angel between 53°-56°, which will reduce the influence of the capacity due to the moisture content.

-

Design with deeper crushing cavity will optimize single cylinder hydraulic cone crusher with more crushing times and higher efficiency.

-

Hydraulic system: The design pressure of the sealing elements is 20MPA, the maximum working pressure is 4MPA. Pressure margin produced by the higher pressure improves the reliability of operation.

-

Imported air cooling system avoids the disadvantage of water cooling system, such as lack of water and leakage of water.

- Adoption of international first-class brand controller, such as Winner, Sun, Danfoss, MTS, etc.

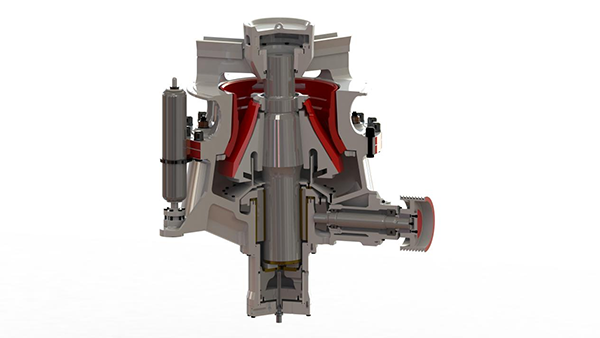

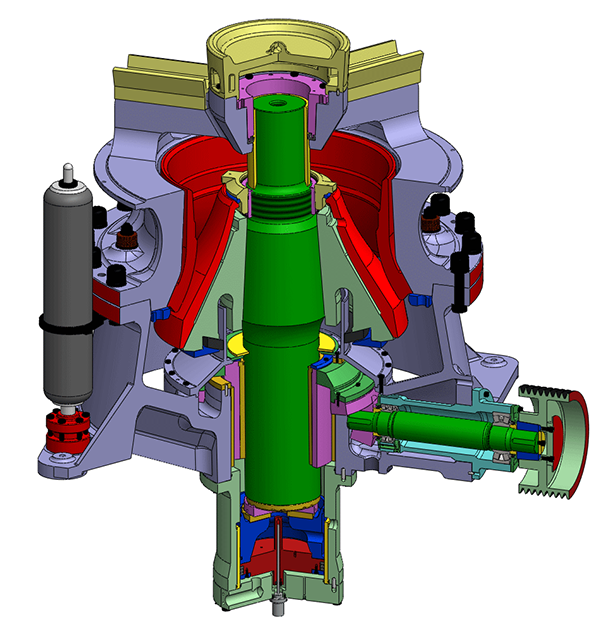

WORKING PRINCIPLE

Single cylinder hydraulic cone crusher is mainly composed of six parts: upper frame body, lower frame body, movable cone, eccentric sleeve, transmission part and hydraulic cylinder. The horizontal shaft driven by the motor makes eccentric sleeve rotating via the gear, then the eccentric sleeve drives the movable cone rotating to realize continuous stone extrusion. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom.