OVERVIEW

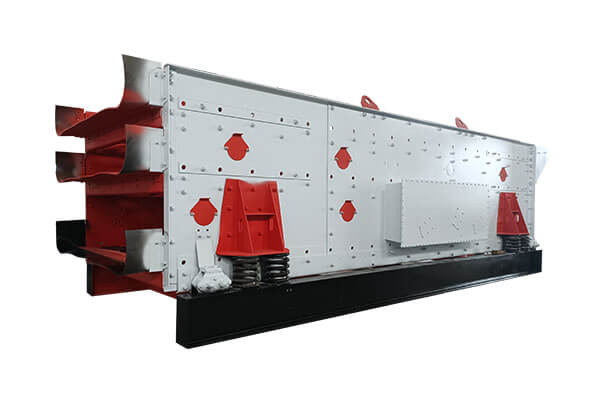

The circular vibrating screen is a high-efficiency and new-type vibrating screen featured by circular vibration and multi-layers. This type of vibrating screen is specially designed for screening sand, aggregates of a quarry, and widely used for product classification in mining, building materials, transportation, energy, chemical products industries. So, it’s a kind of ideal equipment used in the crushing and screening unit. If the screen is equipped with small screen mesh hole, the wet and sticky material can not be screened unless the water spraying method is used.

Advantages

-

1. Adopt block eccentric as exciting force, which is with more power

-

2. Adopt high strength bolts between screen mesh and screening box

-

3. Be connected flexibility and the operation is stable

-

4.Adopt small amplitude, high frequency, and big inclination angle, which makes vibrating screen has high efficiency, big capacity, long lifetime, low power and noise

-

5.Stabilized flexible transmission, diverse configuration and environment friendliness

- 6.Reliable structure, strong exciting force, high efficiency for screening, low noise of vibration, robustness, convenient maintenance, safe operation

Working principle

The vibrating screen mainly consists of screen box, blocking, vibration exciter and gearing parts. Barrel vibration exciter is fixed in the middle of the eccentric shaft, adjusting the weight of eccentric block to change the exciting force to adjust the swing. The bearing is lubricated with grease and sealed with maze.

The exciter with eccentric block is driven by the motor via V-belt to rotate at high speed. The rotary eccentric blocks produce great centrifugal force which forces the screening box to move in circles with certain amplitude. Materials on the leaning screen surface are impacted to continuously do casting or throwing motions. Small particles pass through the screen holes of circular vibrating screen, thus completing the separating process.